Hello makers!

We’ve been quite busy working on the various systems and locations and hardware, but we’ve been very negligent in sharing that on here. I figure I should fix that at least a little bit by posting an update of what we’ve been doing!

After our initial planning stages, when the first round of funding was secured, we proceeded to purchase the various bits-and-pieces we’d need to get started.

Part of the early work involved testing some hardware to satisfy a need a client had, which involved a CNC and lasers… Of course we said yes!

I [Adam] also needed a place to work, both on computers and with a physical hacking workbench. We got to work fixing the shed up with the necessities

One of the more exciting pieces of hardware we’ve acquired are a pair of Cowtech 3d Scanners. They’re not fully configured yet (there’s simply been other priorities, and their home isn’t ready yet either), but they sure are full of exciting possibilities!

And of course there are the raspberry pis. So, so many raspberry pis!

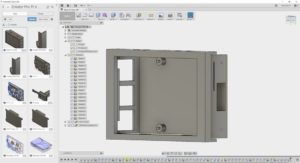

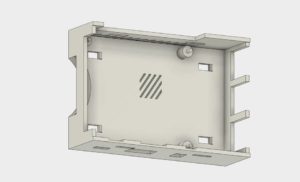

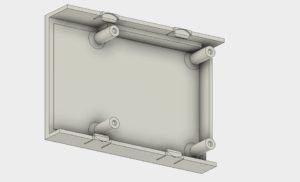

And if you’re using RPI’s, you’ll probably need a case… So Brian set to work designing a case for our projects:

Facebook video of case being printed

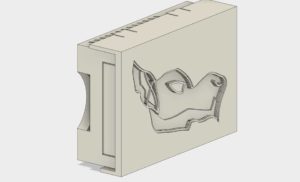

With that success, Brian decided to get phancy. I 100% approve:

Not to neglect the shop (aka garage), we’ve been working hard there too. First it had to be cleaned and the various bits-and-pieces sorted. Then we started to place things in their initial locations to get them functional. That resulted in the computer rack and CNC with it’s computer being setup in the back corner and near the stairs.

But the shop also needs a workbench. Brian sat down and designed one, then we went out and bought the supplies and built it over the course of 2 days.

I think it turned out OK!

There are also other spaces and places to be created, like the Puzzle Table, for example:

And that’s just the physical stuff. We’ve also been hard at work with the network infrastructure, further studio building (kitchen/bar studio almost done!), and other business stuff. Stay tuned!