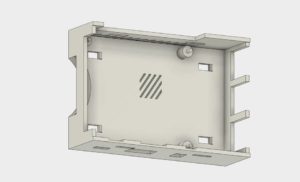

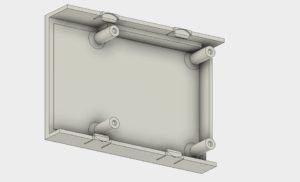

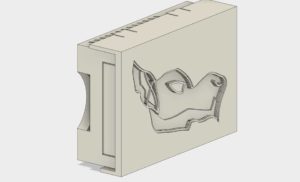

Brian’s boxmod* was starting to be unreliable, and since I’d had my eye on a DIY kit, we figured now was the time.

I’ve been looking at this 75W boxmod kit from Analog Box Mods, so I spec’d one out. It was packed and shipped well within 24 hours, perhaps even the same day I ordered it, and arrived very quickly. Everything was exactly as ordered.

There are really only 8 things to solder:

- 510 pads on the board +/gnd,

- 510 center positive,

- 510 ring negative,

- battery pads on the board +/-,

- battery terminals +/-.

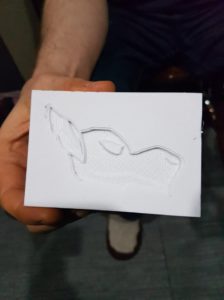

I soldered to the battery terminals first, got them mounted and measured and cut the wires. I screwed this part up for the positive wire and had to cut a bit more off later, but at least I didn’t screw up and make it too short!

The 510 ring was fairly easy to solder, although I think I made it harder on myself for that one by tinning before inserting the wires. It’s probably neater to flux everything and mount the wire through neatly and then solder them together from the bottom. I did it from the top this time, which works but I had to trim the excess off. It would look nicer if it was soldered from the bottom first and then the excess trimmed off.

The 510 center was a bit of a pain, took 2 tries to get it working. Lots of flux down the hole, lots of flux on the wire (cut short to fit with maybe a little exposed), then insert and solder. Not fun, the metal surfaces are small, but it is working OK so far after the 2nd time. The first time pulled out, so that’s no good.

I also had that same wire detach from the board side as well, so it needed some extra attention too.

I cut the wires longer than was strictly necessary, but I think the compromise worked out fine in the end.

I didn’t take any pictures during the soldering, I still find that task rather tedious and I’m especially bad at the pad soldering on boards, so I didn’t think to stop and take any pics, sorry.

*Boxmod: the [usually] box that holds the batteries and control boards for electric vaporizers/e-cigs/whatever you call them.